Advantages of Shirt Interlining: Enhancing Garment Structure

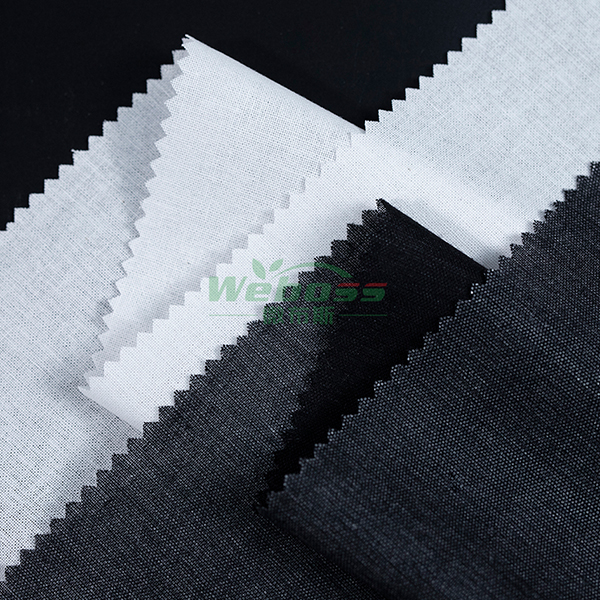

In the textile and garment industry, the importance of shirt interlining is often underestimated. While outer fabrics tend to get most of the attention, it is the interlining that defines a shirt’s shape, feel, and long-term performance. Shirt interlining, positioned between the outer fabric layers, plays a critical role in providing structure, durability, and comfort. Whether for dress shirts, uniforms, or casual wear, high-quality interlining can significantly enhance both aesthetics and function.

This article explores the four major advantages of using superior interlining: structural support, fabric compatibility, durability and performance, and ease of application.

Structural Support and Shape Retention

One of the primary purposes of shirt interlining is to provide structural support. In key areas such as collars, cuffs, plackets, and front panels, interlining ensures that the shirt maintains its shape even after multiple washes and wears. Without it, shirts may appear limp, wrinkled, or unprofessional.

Different interlining thicknesses and stiffness levels allow designers to create varied shirt profiles—from soft, natural drapes to crisp, formal finishes. By carefully selecting the right interlining, manufacturers can craft garments that hold their intended shape while remaining comfortable for the wearer.

Compatibility with Fabrics

Shirt interlining must work harmoniously with a wide range of fabrics—cotton, polyester blends, linen, and more. A mismatch in fabric and interlining can lead to puckering, bubbling, or improper bonding. Advanced interlining solutions are designed for seamless integration, adapting well to different fabric weights and finishes.

To illustrate, here is a simple compatibility chart:

| Outer Fabric Type | Recommended Interlining Type |

|---|---|

| Lightweight Cotton | Soft fusible shirt interlining |

| Medium-Weight Poplin | Standard woven interlining |

| Linen Blend | Light non woven interlining |

| Heavy Twill | Stiff or extra-support interlining |

Using the correct interlining for each fabric type ensures a smooth finish, improved garment quality, and increased customer satisfaction.

Durability and Wash Performance of Shirt Interlining

Shirts are worn, washed, and ironed frequently, especially in professional settings. Therefore, the interlining must offer outstanding durability. High-quality interlinings are engineered to resist shrinkage, maintain their bond after laundering, and withstand repeated ironing.

Non-woven and woven fusible interlining used in shirt manufacturing today often come with special coatings or treatments that enhance their wash performance. These innovations help reduce delamination, bubbling, or weakening of the fused bond over time, thereby extending the garment’s lifespan.

Additionally, interlining helps retain the crisp appearance of collars and cuffs, keeping the shirt looking fresh and structured even after prolonged use.

Efficient Production and Application of Shirt Interlining

From a manufacturing perspective, ease of use is just as important as end-product performance. Modern shirt interlining is designed for fast, efficient application—either through fusing or stitching—reducing labor time and production costs.

Fusible interlinings, in particular, offer the advantage of consistent application through heat presses or fusing machines. They adhere quickly and uniformly, ensuring a clean finish with minimal effort. Some interlinings also come with pre-cut formats tailored to specific shirt sizes or styles, further improving production efficiency.

This convenience allows manufacturers to meet high-volume demands without compromising on quality or precision.

Conclusion

Shirt interlining is more than just a hidden layer—it’s a fundamental component that shapes how a shirt looks, feels, and performs. By offering structural support, fabric compatibility, durability, and ease of application, high-quality interlining directly contributes to garment excellence. It helps create shirts that look professional, wear comfortably, and last longer, making it indispensable in modern apparel manufacturing.

For textile producers and fashion brands seeking consistent, high-performance interlining solutions, Weboss interlining factory offers a trusted range of interlining products tailored to diverse fabric types and production needs.

continue reading

Related Posts

This article explains laminated nonwoven fabric, its structure, materials, functions, applications, and how to choose the right option for different uses.

Spunmelt nonwoven fabric is a multi-layered material combining spunbond and meltblown technologies to deliver strength, breathability, and barrier performance. Manufactured through polymer extrusion, web formation, bonding, and finishing, spunmelt fabrics can feature hydrophilic, anti-bacterial, anti-static, and “Three-Anti” treatments.

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.