Exploring the Role of Spunmelt Nonwoven Fabric in Modern Applications

Dans un monde du textile en constante évolution, les matériaux non tissés avancés sont devenus indispensables pour répondre aux exigences des secteurs de la santé, de l’hygiène, de l’emballage et de l’industrie. Parmi ces innovations, le non tissé spunmelt est apparu comme l’une des solutions les plus polyvalentes et efficaces. Reconnu pour son équilibre entre résistance, douceur et rentabilité, le non tissé spunmelt continue de façonner les industries modernes. Chez Weboss, nous veillons à ce que notre expertise en conception, nos pratiques d’approvisionnement durables et nos processus de production méticuleux fournissent un non tissé spunmelt qui répond constamment aux attentes mondiales.

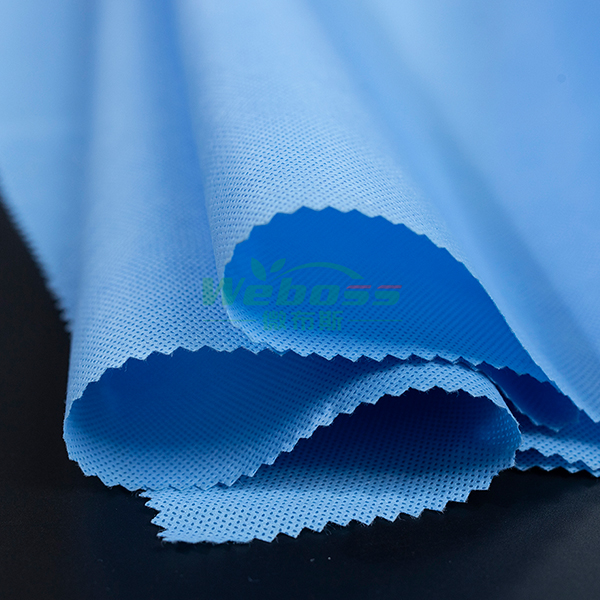

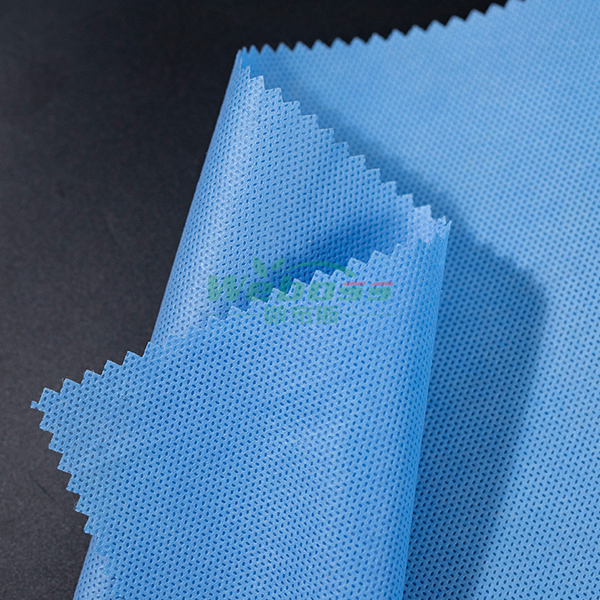

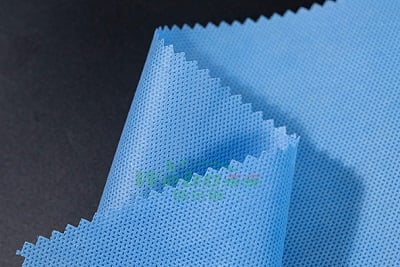

Propriétés du non tissé spunmelt

La performance distinctive du non tissé spunmelt découle de son processus de production unique, où les couches spunbond et meltblown sont combinées pour créer un matériau composite. Cette structure offre une haute efficacité de filtration, une excellente résistance à la traction et une texture uniforme. Les couches spunbond apportent durabilité et douceur, tandis que la couche meltblown renforce les propriétés barrière, rendant le tissu adapté aux applications de protection et d’hygiène. Ces caractéristiques confèrent au non tissé spunmelt un avantage concurrentiel sur les textiles conventionnels dans de multiples industries.

Applications du non tissé spunmelt à travers les secteurs

L’adaptabilité du non tissé spunmelt lui permet de répondre à des exigences diverses dans différents secteurs. Dans le domaine de la santé, il est utilisé pour les drapes chirurgicales, les blouses et les masques de protection en raison de sa résistance aux fluides et de son confort. En hygiène, il est largement adopté dans les couches pour bébés, les produits d’incontinence pour adultes et les produits d’hygiène féminine, où la douceur et la sécurité sont essentielles. Les applications industrielles incluent l’emballage, la filtration et les combinaisons de protection, tandis que l’agriculture bénéficie de son utilisation dans les bâches pour cultures qui sont à la fois respirantes et durables. Ce large éventail d’applications reflète la manière dont le non tissé spunmelt est devenu intégrant à la vie quotidienne.

Comparaison du non tissé spunmelt avec d’autres non tissés

Pour comprendre la valeur du non tissé spunmelt, il est important de le comparer à d’autres types de non tissés. La combinaison des technologies spunbond et meltblown confère aux tissus spunmelt des caractéristiques de performance uniques qui diffèrent des alternatives à couche unique.

| Type de tissu | Propriétés clés | Applications courantes |

| Non tissé spunbond | Résistant, léger, respirant | Emballage, agriculture, produits jetables |

| Non tissé meltblown | Fibres fines, haute efficacité de filtration | Masques, filtres, matériaux absorbants |

| Non tissé spunmelt | Durable, doux, protection barrière | Blouses médicales, couches, combinaisons industrielles |

Cette comparaison met en évidence la manière dont le non tissé spunmelt intègre les forces des technologies spunbond et meltblown, le rendant plus polyvalent et plus adapté aux applications nécessitant durabilité et protection.

Durabilité et sécurité environnementale

À mesure que les industries évoluent vers des pratiques plus vertes, le non tissé spunmelt a gagné en attention pour son rôle potentiel en matière de durabilité. Chez Weboss, les matières premières sont soigneusement sélectionnées pour garantir la sécurité, la qualité et la conformité aux normes environnementales. Le processus de production évite les produits chimiques nocifs et se concentre sur la réduction des déchets, tout en veillant à ce que le tissu conserve ses propriétés fonctionnelles. Pour des applications telles que l’hygiène et l’usage médical, cet équilibre entre sécurité et responsabilité environnementale fait du non tissé spunmelt un choix de plus en plus important pour les industries modernes.

À l’avenir, le rôle du non tissé spunmelt devrait s’étendre davantage à mesure que les industries exigent des matériaux plus fiables, rentables et durables. Sa capacité à offrir douceur et confort sans compromettre la résistance ou la protection le positionne comme une solution clé pour les applications de nouvelle génération. Que ce soit dans le domaine de la santé, de l’hygiène ou de l’usage industriel, le non tissé spunmelt continuera d’influencer l’innovation et l’efficacité dans de multiples domaines.

continue reading

Related Posts

This article explains laminated nonwoven fabric, its structure, materials, functions, applications, and how to choose the right option for different uses.

Spunmelt nonwoven fabric is a multi-layered material combining spunbond and meltblown technologies to deliver strength, breathability, and barrier performance. Manufactured through polymer extrusion, web formation, bonding, and finishing, spunmelt fabrics can feature hydrophilic, anti-bacterial, anti-static, and “Three-Anti” treatments.

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.