Meltblown Nonwoven Fabric에 대해 알아야 할 사항은 무엇입니까?

Meltblown nonwoven fabric became widely recognized during the global mask shortage, but its applications go far beyond medical use. This material has very fine fibers, excellent filtration properties, and a unique structure that sets it apart from other nonwovens. Whether you work in hygiene products, filtration, industrial wipes, or environmental protection, meltblown fabric plays a key role. In this article, I’ll walk you through its production process, types, features, and practical uses.

What Is Meltblown Nonwoven Fabric?

Meltblown nonwoven is a type of fabric made by extruding melted polymer—usually polypropylene—through extremely small nozzles. High-speed hot air stretches the fibers until they become ultra-fine, often just a few microns in diameter. These fibers fall randomly onto a conveyor belt and form a dense, web-like structure.

Because of these fine fibers, meltblown fabric has:

-

excellent filtration efficiency

-

high softness

-

strong absorption capability

-

very low linting

This makes it ideal for filters, masks, wipes, and oil-absorbent materials.

How Is Meltblown Fabric Manufactured?

1. Polymer Feeding and Melting

Most meltblown fabric uses polypropylene (PP). The polymer is melted and prepared for extrusion.

2. Fiber Formation

The molten polymer is pushed through a row of tiny nozzles. At the same time, hot air jets blow the fibers into ultra-thin strands.

3. Web Formation

The blown fibers land on a moving belt, creating a random, fluffy fiber web.

4. Bonding and Stabilizing

The web is lightly bonded using hot air or calendering to give the fabric its strength and uniformity.

5. Post-Treatment (Optional)

Depending on use, meltblown may undergo:

-

electrostatic charging (critical for mask filters)

-

hydrophobic or hydrophilic treatment

-

oil-absorbent finishing

Each treatment changes how the fabric performs in different industries.

What Makes Meltblown Fabric So Special?

Very Fine Fibers

Meltblown fibers are much thinner than spunbond fibers, which gives the material great filtering capability.

High Filtration Efficiency

Electrostatically charged meltblown fabric captures particles such as dust, bacteria, and aerosols without making breathing difficult. This is why it’s used in N95 and surgical mask filters.

Soft and Flexible

Despite its filtration strength, the fabric feels soft and lightweight.

Good Oil Absorption

The fine fiber structure allows meltblown to absorb many times its own weight in oil, making it useful for environmental cleanup.

Low Linting

It doesn’t easily shed fibers, which is important for medical and electronics applications.

What Types of Meltblown Fabric Are Common?

1. Standard Meltblown PP Fabric

Used for wipes, filtration layers, and absorbent materials.

2. Electrostatic Meltblown Fabric (ES/Meltblown)

Charged through corona or electret processes. Mainly used in mask filtration layers.

3. Water-Repellent Meltblown

Used in some hygiene or protective products where moisture control matters.

4. Oil-Absorbent Meltblown

Designed to quickly absorb oils—often used in industrial workshops or spill control products.

5. 복합 용융부직포 구조

때로는 스펀본드 레이어와 결합하여 다음을 형성:

-

SMS

-

SMMS

-

SSMMS

이러한 구조는 강도, 여과 및 차단 성능을 향상시킵니다.

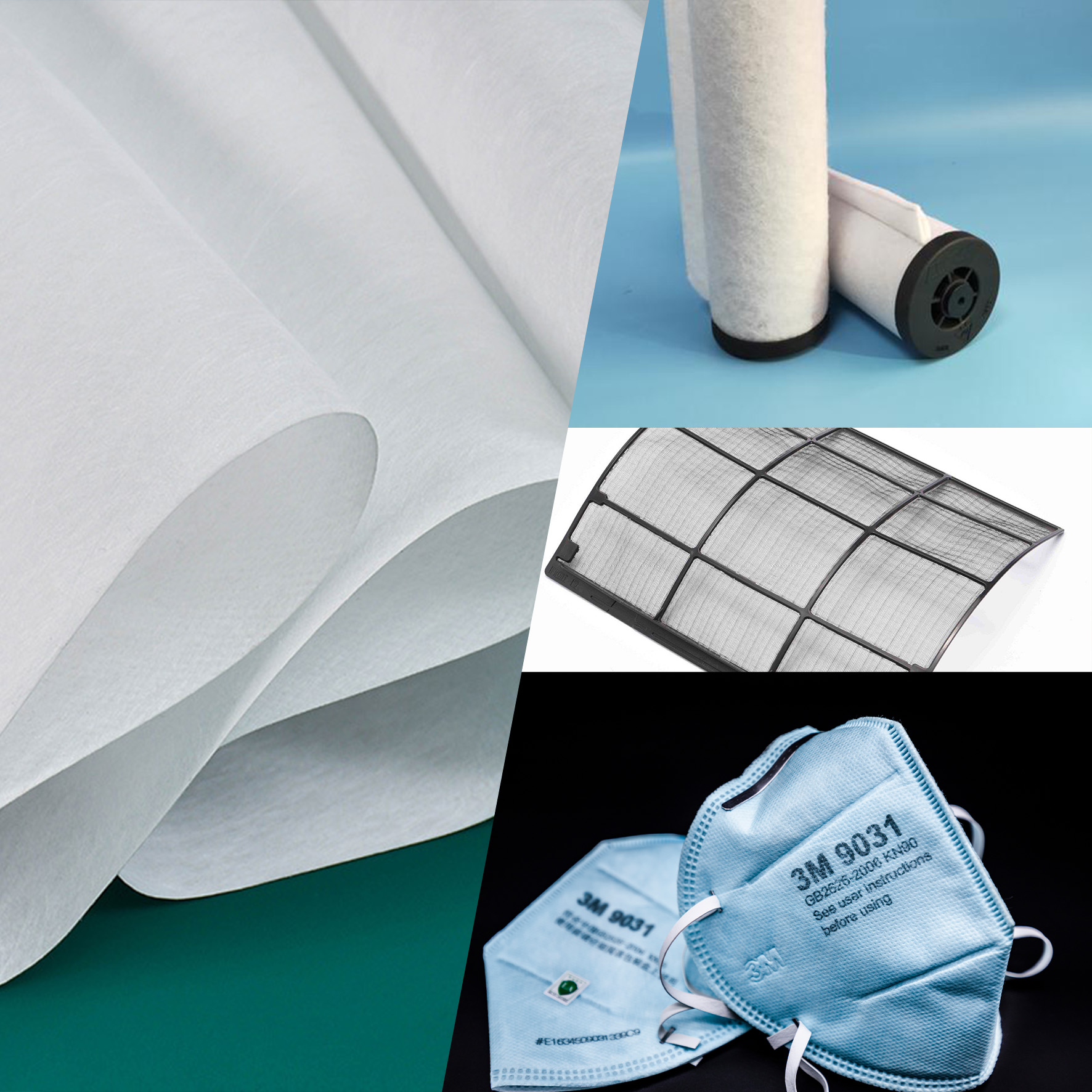

용융부직포의 주요 응용 분야는 무엇인가요?

마스크 및 호흡기

용융부직포는 다음의 핵심 여과 레이어입니다:

-

N95

-

KN95

-

수술용 마스크

-

일회용 의료용 마스크

용융부직포가 없으면 이러한 마스크는 여과 기준을 충족할 수 없습니다.

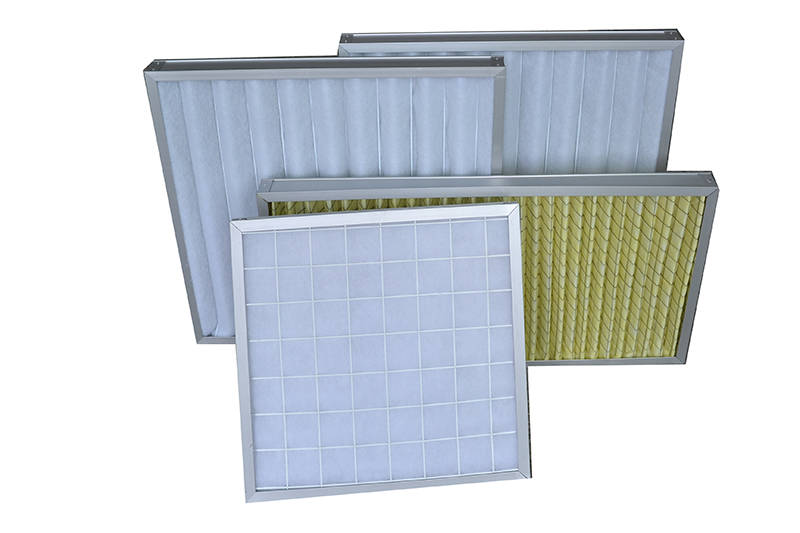

공기 및 액체 여과

미세 섬유는 다음에서 먼지, 박테리아 및 아주 작은 입자를 여과하는 데 도움이 됩니다:

-

공기 청정기

-

HVAC 시스템

-

진공 청소기 필터

-

산업용 여과 시스템

흡수성 재료

용융부직포는 다음에 널리 사용됩니다:

-

기름 제거 패드

-

산업용 흡수 롤

-

해양 유출 사고 제어

위생 및 청소 용품

일부 물티슈 및 가정용 티슈에는 흡수성 또는 여과 성능 향상을 위해 용융부직포 레이어가 포함되어 있습니다.

보호복

의료용 가운 및 보호복과 같은 복합 부직포 구조에 사용됩니다.

용융부직포 품질에 영향을 미치는 요인은 무엇인가요?

섬유 직경

더 미세한 섬유가 일반적으로 더 나은 여과 성능을 가집니다.

웹의 균일성

매끄럽고 균일한 표면은 더 나은 가공 품질을 나타냅니다.

전기적 충전 안정성

여과 제품에 특히 중요합니다. 불안정한 충전은 시간이 지남에 따라 여과 효율을 저하시킵니다.

단위면적중량 (GSM)

다른 GSM 수준은 다른 목적으로 사용됩니다. 더 높은 GSM은 일반적으로 더 나은 여과 또는 흡수성을 제공합니다.

MFI (용융 유동 지수) (PP의)

MFI는 고분자가 미세 섬유를 얼마나 잘 형성하는지에 영향을 미칩니다. 고MFI PP (1500+) 는 종종 용융부직포에 사용됩니다.

올바른 용융부직포를 선택하는 방법은 무엇인가요?

용융부직포를 선택할 때 다음을 고려하십시오:

-

최종 용도 (마스크, 필터, 흡수 패드, 티슈)

-

요구되는 여과 효율

-

전기적 충전이 필요한지 여부

-

GSM requirement

-

oil absorption or hydrophobic property

-

compliance with local standards (ASTM, EN, GB)

A knowledgeable supplier should be able to match the correct specification to your product.

FAQ

Q1: Is meltblown fabric washable?

Generally no. Washing removes the electrostatic charge and damages the fiber structure, reducing filtration.

Q2: What GSM is used for mask filtration?

Commonly 20–30 GSM, depending on filtration requirements.

Q3: Is meltblown fabric environmentally friendly?

Standard PP meltblown is not biodegradable, but recycling options exist. Some newer bio-based versions are being developed.

Q4: What makes meltblown different from spunbond?

Spunbond fibers are thicker and stronger, while meltblown fibers are extremely fine and better for filtration.

Why Choose Shanghai Weboss New Material Technology Co.,Ltd.?

Shanghai Weboss New Material Technology Co.,Ltd. has years of experience supplying nonwoven fabrics—including meltblown, spunbond, SMS, and various composite materials—to customers worldwide. Our meltblown products are produced with stable MFI raw materials, strict quality control, and consistent filtration performance. Whether you need electrostatic meltblown for masks or absorbent-grade meltblown for industrial use, we provide reliable specifications, testing reports, and export-ready documentation.

We focus on stable supply, technical support, and long-term cooperation. If you’re looking for a dependable meltblown supplier, our team is ready to assist you.

continue reading

Related Posts

This article explains laminated nonwoven fabric, its structure, materials, functions, applications, and how to choose the right option for different uses.

Spunmelt nonwoven fabric is a multi-layered material combining spunbond and meltblown technologies to deliver strength, breathability, and barrier performance. Manufactured through polymer extrusion, web formation, bonding, and finishing, spunmelt fabrics can feature hydrophilic, anti-bacterial, anti-static, and “Three-Anti” treatments.

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.