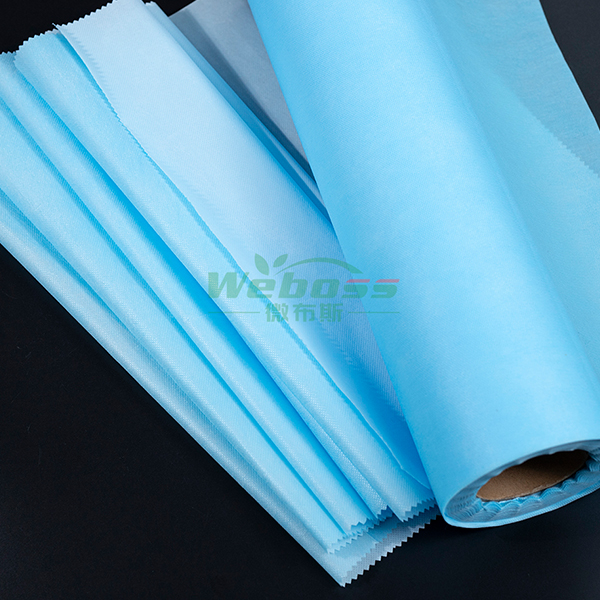

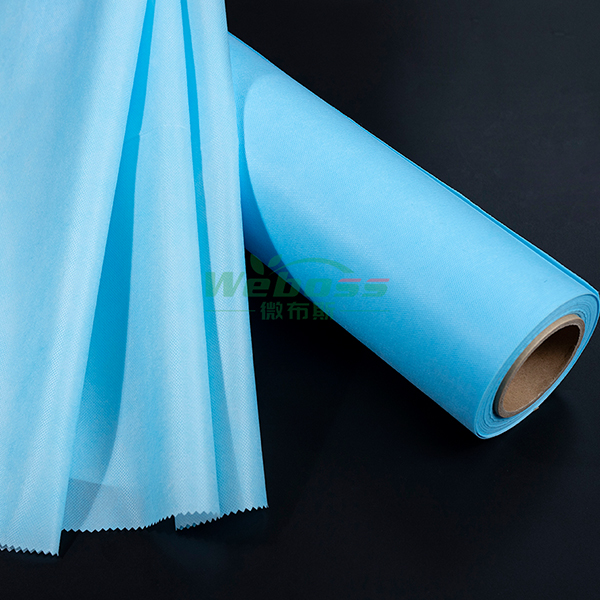

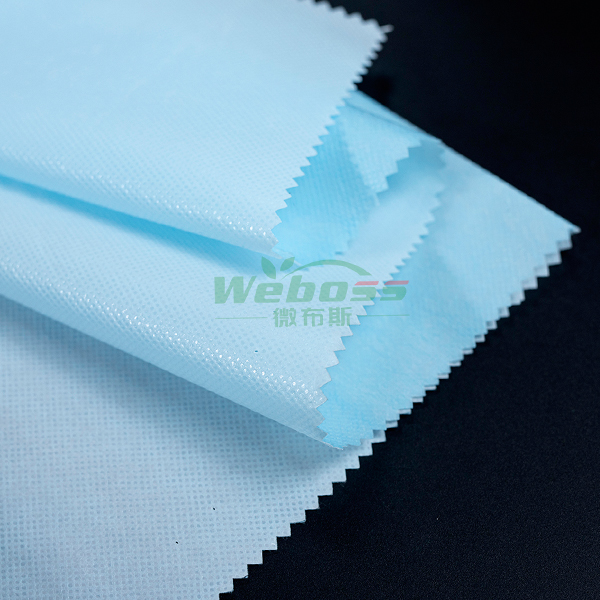

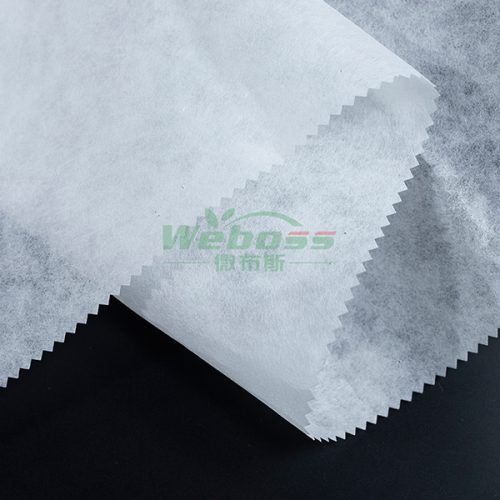

Composite Nonwoven Fabric

Composite Nonwoven Fabric is produced by laminating or coating nonwoven fabrics with breathable films, aluminum layers, or other materials through advanced technologies like glue spraying, ultrasonic bonding, and PE coating. Available in SF (Nonwoven Fabric + Breathable Film) and SFS (Nonwoven Fabric + Breathable Film + Nonwoven Fabric) series, these composites offer superior physical strength, excellent water barrier properties, and high hydrostatic head performance. They are widely applied in medical, hygiene, industrial, and automotive sectors for protective clothing, absorbent materials, and more.

product introduce

Composite Nonwoven Fabric Product Highlights:

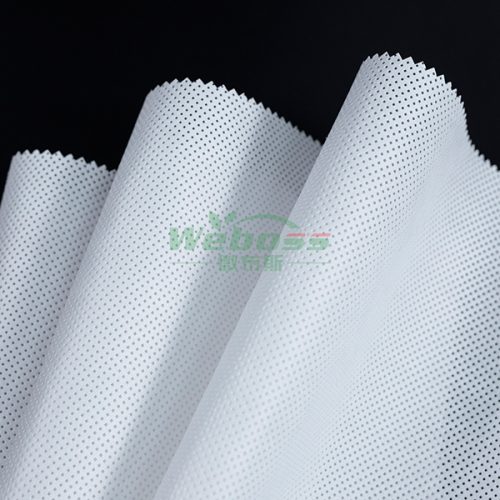

1. Versatile Composition Options: Includes nonwoven fabric paired with PE film, aluminum film, spunlace, or meltblown materials to meet diverse application needs.

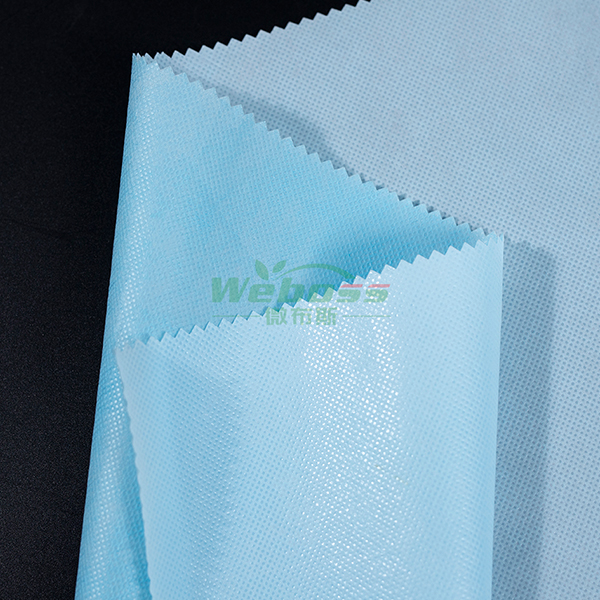

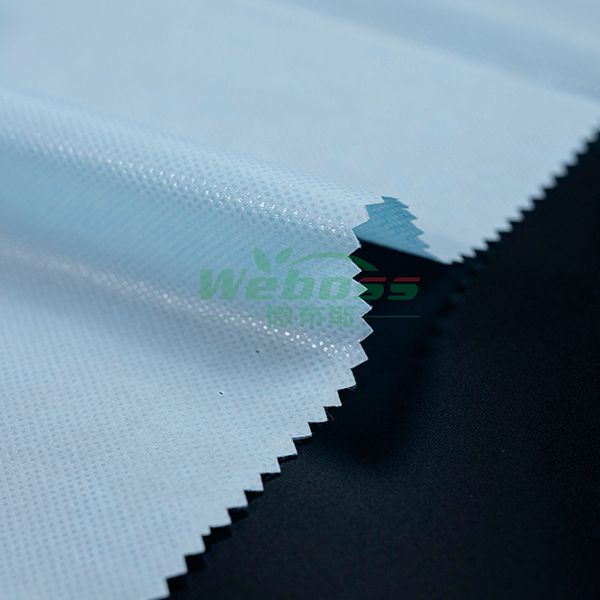

2. Enhanced Performance: Offers excellent water resistance, air permeability, and high tensile strength, ensuring reliability across applications.

3. Innovative Technology: Manufactured using ultrasonic bonding and advanced coating processes for seamless integration and durability.

4. Wide Applications: Suitable for medical absorbent materials, hygiene products, automotive insulation, and industrial protective gear.

Product Advantages of Composite Nonwoven Fabric

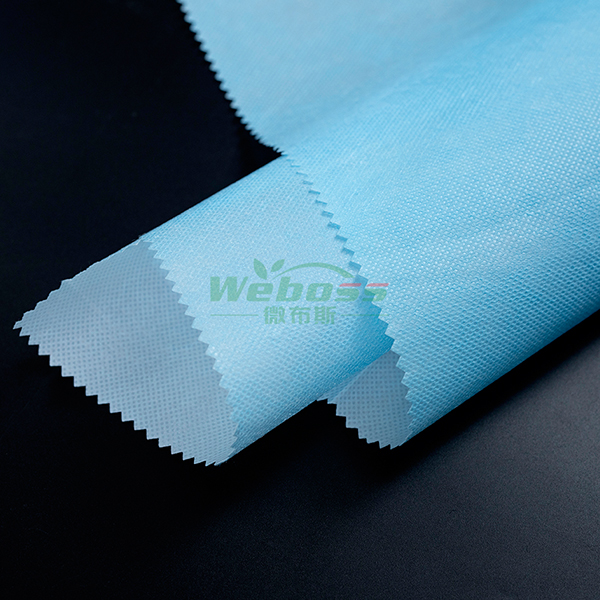

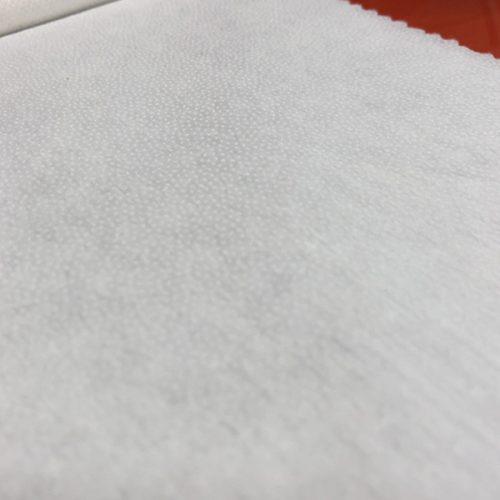

Composite nonwoven fabric is engineered by laminating, coating, or bonding two or more material layers, each selected for a specific function. Instead of relying on a single material to meet all requirements, composite structures allow manufacturers to combine strength, protection, comfort, and functionality in one fabric.

Typical composite structures may include spunbond, spunlace, meltblown, film, or coated layers, creating materials that deliver controlled breathability, liquid resistance, barrier performance, or mechanical stability. This makes composite nonwoven fabric especially suitable for applications with multi-functional performance demands.

Compared with single-layer nonwovens, composite fabrics provide greater design flexibility, better performance consistency, and broader application adaptability.

Composite Nonwoven vs. Single-Layer Nonwoven—When to Use Composite Structures

Composite nonwoven fabric is not intended to replace single-layer nonwovens in all applications. Instead, it is chosen when one material alone cannot meet the full performance requirement.

Single-layer nonwovens are often sufficient for:

- Basic hygiene or disposable uses

- Applications with limited barrier or strength requirements

Composite nonwoven fabrics are preferred when products require:

- Liquid or chemical resistance

- Enhanced filtration or barrier performance

- Controlled breathability

- Improved durability or dimensional stability

- Multi-functional performance in one material

Choosing a composite structure allows product designers to optimize each layer for its role, rather than over-engineering a single material.

Functional Treatments & Structural Customization Options

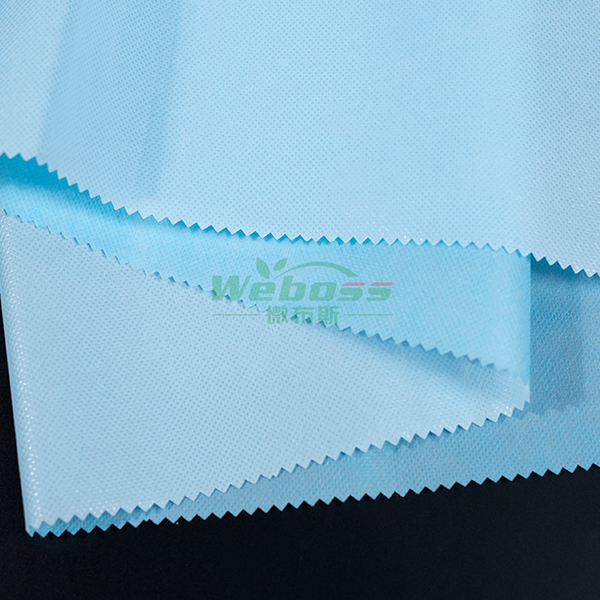

Composite nonwoven fabric offers extensive customization in both structure and surface functionality:

- Laminated or coated constructions (breathable or non-breathable)

- Hydrophilic/hydrophobic layer design

- Antibacterial or antimicrobial treatments

- Anti-static and UV-resistant options

- Film thickness and coating weight control

- Layer combination flexibility (S+M, S+Film, Spunlace+Film, etc.)

- Customized width, weight, and roll format

Weboss works with customers to define layer composition and bonding methods that align with real application requirements, not just theoretical performance.

Common Applications of Composite Nonwoven Fabric

Due to its structural versatility, composite nonwoven fabric is widely used in:

- Medical and healthcare protective products

- Hygiene products and medical underpads

- Protective apparel and disposable garments

- Industrial protective covers and wraps

- Construction and roofing membranes

- Filtration and barrier applications

- Agricultural protection materials

Composite structures are especially valuable in applications where performance reliability and functional balance are critical.

FAQ

What types of nonwovens can be combined in composite fabrics?

Common combinations include spunbond, meltblown, spunlace, films, and coated layers.

Is composite nonwoven fabric breathable?

Breathability depends on structure. Breathable and non-breathable options are both available.

Can composite fabrics be customized for specific applications?

Yes. Structure, layer thickness, treatments, and finishing can be tailored to application needs.

Are composite nonwovens suitable for medical use?

Yes. Many composite structures are designed specifically for medical and hygiene standards.

Why Choose Weboss?

Weboss focuses on application-driven composite nonwoven solutions, not one-size-fits-all products.

- Experience with laminated and coated nonwoven structures

- Flexible customization of layers and treatments

- Stable production and quality consistency

- Support from material selection to final application

- Reliable supply for global markets

- Responsive technical and commercial communication

Choosing Weboss means working with a partner who understands how to turn layered design into reliable product performance.

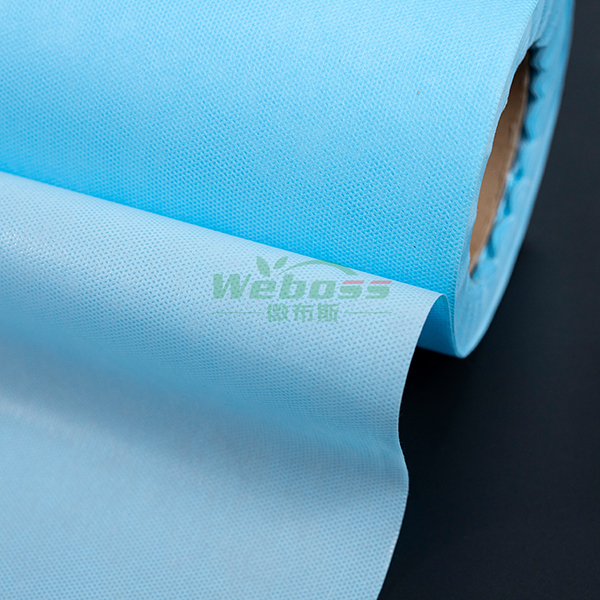

additional information

| Minimum Order Quantity | 500kg per type |

|---|---|

| Certification | OEKO-TEX, GRS, SGS |

| Price Range | USD $1.5 – $2.5/kg (Depending on material and weight) |

| Packaging | Roll packed in PE plastic bags, with an outer strong woven polybag |

| Transportation | Via sea, air, or express logistics |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 2,000,000 meters |

| Roll Length | 100m-1000m/roll |

| Special Customization | Available for color, weight, and width upon request |

Composite Nonwoven Fabric Product Specifications

| Product Series | Description | Material | Applications |

| SF | Non Woven Fabric + Breathable Film | Non Woven Fabric + PE Film | Medical |

| SFS | Non Woven Fabric + Breathable Film + Non Woven Fabric | Non Woven Fabric + Aluminum Film | Hygiene |

| Non Woven Fabric + Spunlace Non Woven Fabric | Protective | ||

| Non Woven Fabric + Meltblown Fabric + Non Woven Fabric | Industrial | ||

| Non Woven Fabric + PE Film + Non Woven Fabric | Automotive | ||

| Spunlace Non Woven Fabric + Breathable Film + Non Woven Fabric | |||

| Non Woven Fabric + Thermal Insulation Material + Aluminum Film | |||

| Aluminum Film + Thermal Insulation Material + Non Woven Fabric – Ultrasonic Composite | |||

| Non Woven Fabric + Breathable Film + Non Woven Fabric – Ultrasonic Composite | |||

| Medical Absorbent Material: PE Film + Absorbent Material | |||

| Medical Absorbent Material: PE Film + Hydrophilic Nonwoven or Spunlace Non Woven Fabric |

Related Products

Stay Ahead With Weboss Updates

This article explains laminated nonwoven fabric, its structure, materials, functions, applications, and how to choose the right option for different uses.

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.

Spunmelt nonwoven fabric is a multi-layered material combining spunbond and meltblown technologies to deliver strength, breathability, and barrier performance. Manufactured through polymer extrusion, web formation, bonding, and finishing, spunmelt fabrics can feature hydrophilic, anti-bacterial, anti-static, and “Three-Anti” treatments.