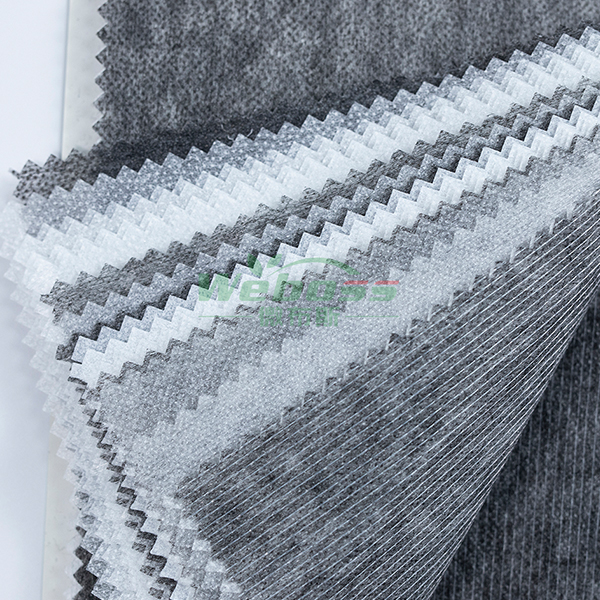

Thermal Bond Nonwoven Interlining

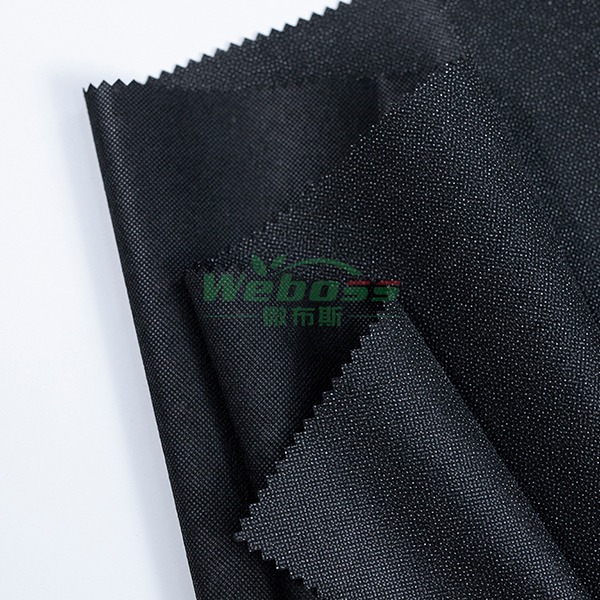

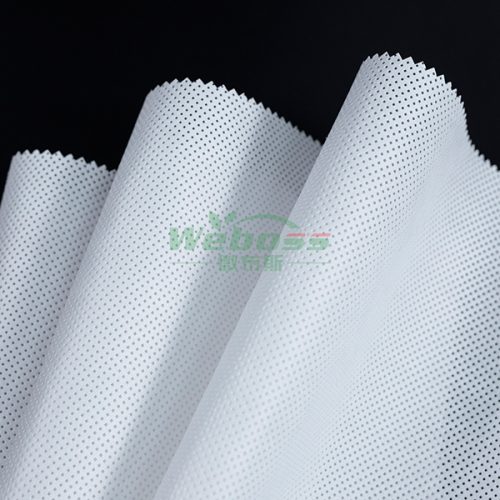

Thermal Bond Nonwoven Interlining,is engineered using advanced thermal bonding techniques. It is lightweight, smooth, and highly breathable, ensuring optimal comfort and seamless integration into garments. This interlining is widely used in men’s and women’s garments, including full fronts, collars, and other small parts of clothing. As a trusted nonwoven interlining factory, Weboss provides consistent quality and tailored solutions to meet diverse garment manufacturing needs.

product introduce

Thermal Bond Nonwoven Interlining Product Highlights

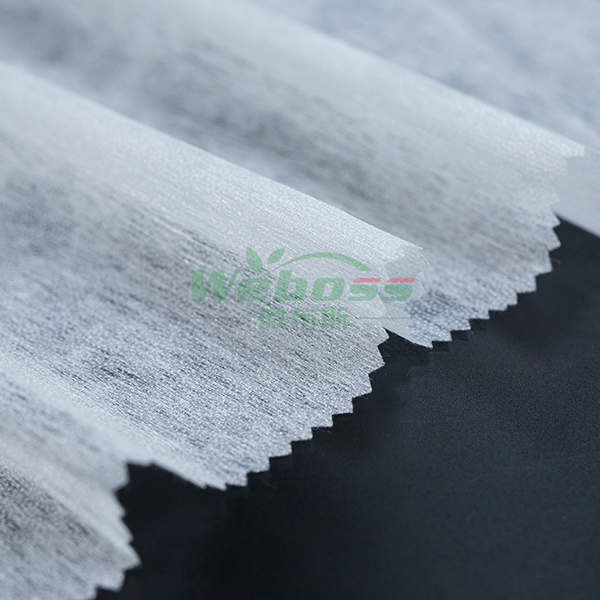

1.Lightweight and Smooth Texture

Provides a soft and smooth finish, ensuring comfort and an enhanced garment appearance.

2.High Breathability

Designed with air-permeable fibers, this interlining is ideal for lightweight and breathable clothing.

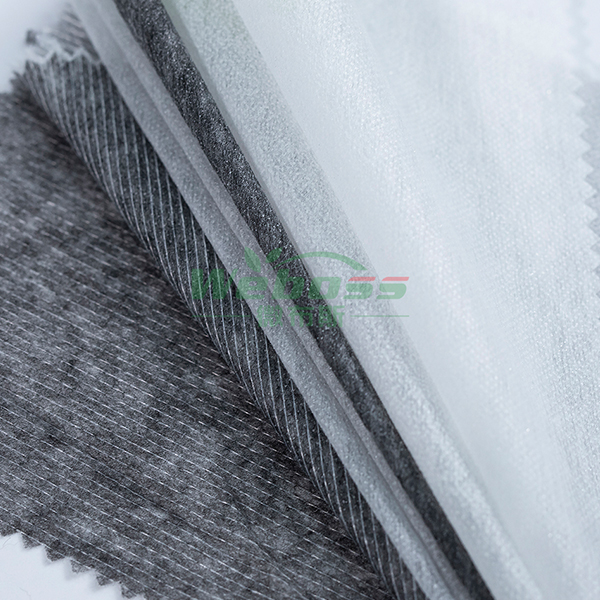

3.Reliable Adhesion Performance

Heat-bonding technology ensures a uniform and secure bond with various fabric types.

4.Versatility in Application

Suitable for diverse garment designs, including blouses, casual wear, and tailored clothing.

additional information

| Material | 100% Polyester / 50% Polyester + 50% Nylon / 20% Polyester + 80% Nylon |

|---|---|

| Width | 90cm, 100cm, 150cm |

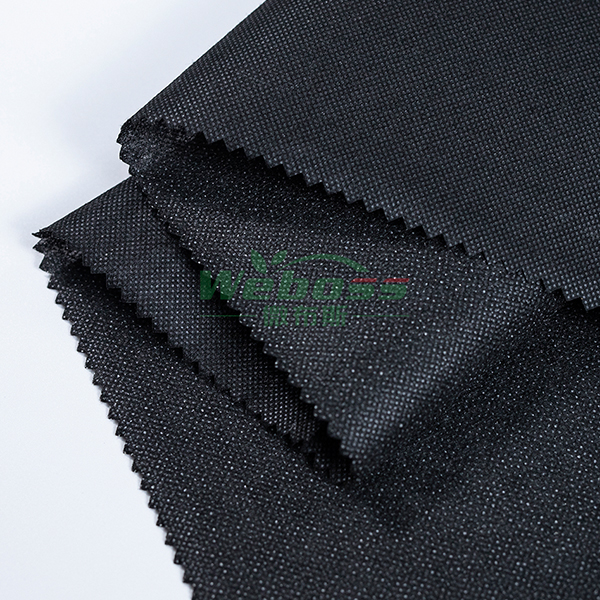

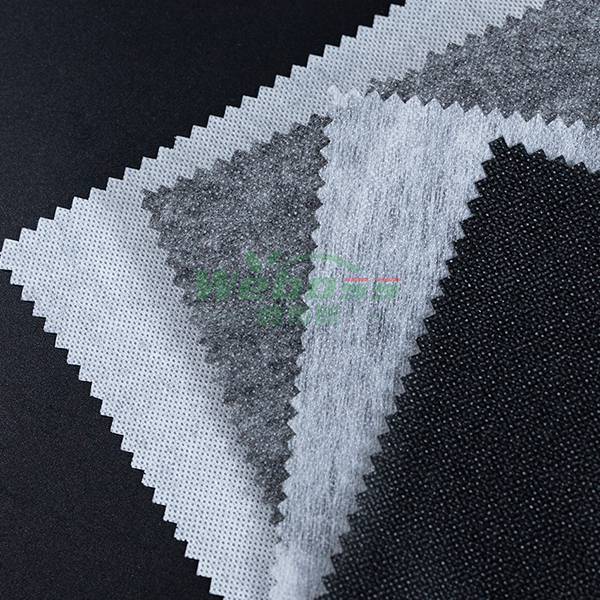

| Color | White, Optical White, Charcoal, Grey, Black |

| Weight | 24gsm – 85gsm |

| MOQ (Minimum Order Quantity) | 1000 meters |

| Certificates | OEKO-TEX, SGS, GRS |

| Price | 0.3 – 2.0 USD per meter |

| Packaging | PE plastic bag and Nylon bag; the roll packed by transparent strong plastic bag, the outside by strong woven polybag. |

| Transportation | By sea, air, or express |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union |

| Delivery Time | 7-15 days |

| Monthly Production | 1,000,000 meters |

| Roll Length | 100 meters per roll |

| Thermal Properties | Fusing temperature range: 110-130掳C |

| Features | Lightweight, durable, strong bonding properties, available in multiple color options, resistant to enzyme and garment washing. |

| Applications | Full front and small parts of garments, suitable for enzyme wash products, low melt fusing products, leather fabric applications. |

Related Products

Stay Ahead With Weboss Updates

This article explains laminated nonwoven fabric, its structure, materials, functions, applications, and how to choose the right option for different uses.

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.

Spunmelt nonwoven fabric is a multi-layered material combining spunbond and meltblown technologies to deliver strength, breathability, and barrier performance. Manufactured through polymer extrusion, web formation, bonding, and finishing, spunmelt fabrics can feature hydrophilic, anti-bacterial, anti-static, and “Three-Anti” treatments.