What Should You Know About Needle Punched Nonwoven Fabric?

What Is Needle Punched Nonwoven Fabric?

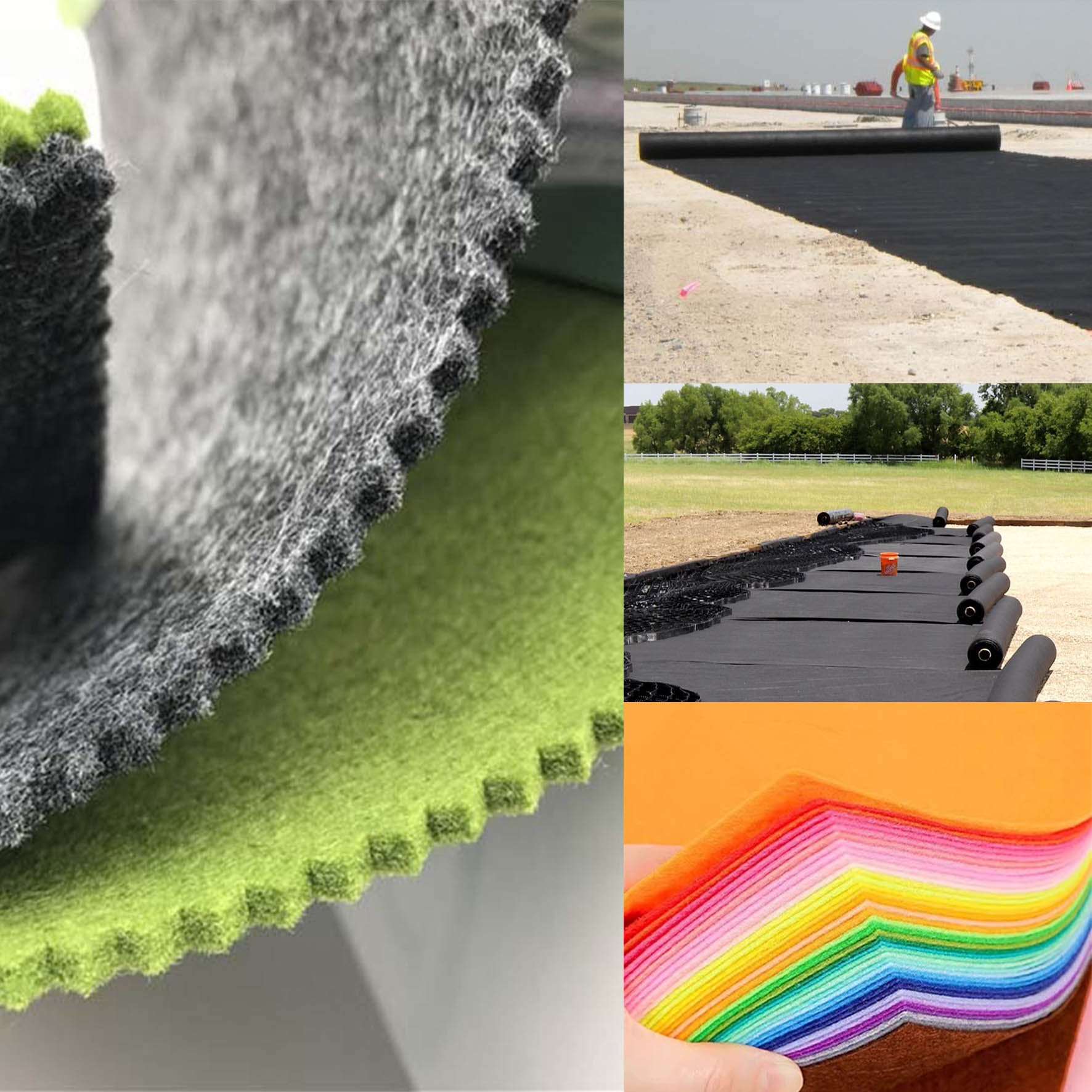

Needle punched nonwoven fabric is a type of nonwoven material made by mechanically bonding fibers together. Instead of using glue or heat, barbed needles repeatedly punch through a fiber web, locking the fibers together.

This process creates a fabric that is strong, stable, and breathable. It is widely used in industrial, construction, filtration, and protective applications.

How Is Needle Punched Nonwoven Fabric Made?

Fiber Web Formation

Fibers are first opened, mixed, and laid into a loose web. The fibers can be polyester, polypropylene, or other synthetic materials.

Needle Punching Process

Thousands of barbed needles move up and down through the web. As the needles penetrate the fibers, they pull and entangle them, forming a solid fabric structure.

Finishing Treatments

Depending on the application, the fabric may be heat-set, calendered, coated, or laminated to improve strength, thickness, or surface performance.

Common Materials Used in Needle Punched Nonwoven Fabric

Polyester (PET)

Polyester needle punched fabric offers high strength, good chemical resistance, and long service life. It is commonly used in geotextiles and filtration.

Polypropylene (PP)

PP needle punched fabric is lightweight, cost-effective, and resistant to moisture. It is widely used in drainage, separation layers, and disposable applications.

Blended Fibers

Some needle punched fabrics use blended fibers to balance strength, flexibility, and cost, depending on project requirements.

Key Characteristics of Needlepunched Nonwoven Fabric

-

High tensile strength

-

Good air and water permeability

-

Stable structure without chemical binders

-

Strong resistance to tearing and puncture

-

Flexible thickness and weight options

These features make needle punched nonwoven fabric suitable for demanding environments.

Technical Overview of Needlepunched Nonwoven Fabric

| Item | Description |

|---|---|

| Manufacturing Process | Mechanical fiber entanglement using barbed needles |

| Common Materials | Polyester (PET), Polypropylene (PP), Fiber blends |

| Typical Weight Range | 80–1000 gsm |

| Thickness | Medium to thick (customizable) |

| Air Permeability | High |

| Water Permeability | High (can be treated or laminated if needed) |

| Tensile Strength | High, suitable for heavy-duty use |

| Main Functions | Filtration, separation, drainage, reinforcement |

| Common Applications | Geotextile, filtration, automotive, industrial protection |

Main Applications of Needlepunched Nonwoven Fabric

Geotextile and Civil Engineering

Used for filtration, separation, drainage, and soil reinforcement in roads, railways, and construction projects.

Filtration Materials

Applied in air filters, liquid filtration systems, and dust collection due to its porous structure.

Automotive and Industrial Uses

Used in car interiors, insulation layers, sound absorption, and protective padding.

Protective and Packaging Materials

Provides cushioning, surface protection, and reinforcement in industrial packaging.

Needlepunched Nonwoven Fabric vs Other Nonwoven Types

Compared with spunbond or meltblown fabrics, needle punched nonwoven fabric is thicker and stronger. It focuses more on mechanical performance rather than softness or fine filtration.

Each nonwoven type serves different purposes, and needle punched fabric is often chosen when durability is a priority.

How to Choose the Right Needlepunched Nonwoven Fabric

When selecting needle punched nonwoven fabric, consider:

-

Fiber material (PET or PP)

-

Fabric weight and thickness

-

Strength and elongation requirements

-

Application environment

-

Cost and service life expectations

Choosing the right specification helps avoid overuse or underperformance.

FAQ

Is needlepunched nonwoven fabric waterproof?

No, it is usually breathable and permeable, but it can be laminated or coated if waterproof performance is required.

Can needle punched fabric be customized?

Yes, weight, thickness, width, and material can be adjusted based on application needs.

Is needle punched fabric environmentally friendly?

Many types are recyclable, especially those made from polyester or polypropylene.

Why Choose Shanghai Weboss New Material Technology Co.,Ltd.?

-

Wide Product Range

Needle punched, spunbond, spunlace, and other nonwoven fabrics available. -

Stable Quality Control

Consistent specifications across batches. -

Competitive Pricing

Cost-effective solutions for long-term supply. -

Application-Oriented Support

Product recommendations based on real usage needs. -

Export Experience

Professional service for international customers.

continue reading

Related Posts

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.

This article explains what needle punched nonwoven fabric is, how it is made, its materials, key features, and common applications.

This article explains nonwoven geotextile fabric, its materials, functions, applications, and how it works in real projects.