Hot Air Nonwoven Fabric

Hot Air Nonwoven Fabric is a high-quality thermally bonded nonwoven material made through hot air-through technology. This process bonds fibers by melting their surface under hot air, creating a soft, fluffy, and breathable structure without using adhesives. Depending on the fiber composition, hot air nonwoven fabric can be classified into ES nonwoven fabric (PP+PE or PET+PE) and 100% cotton hot air nonwoven fabric. It is widely used in hygiene, medical, skincare, and filtration applications.

product introduce

Product Overview

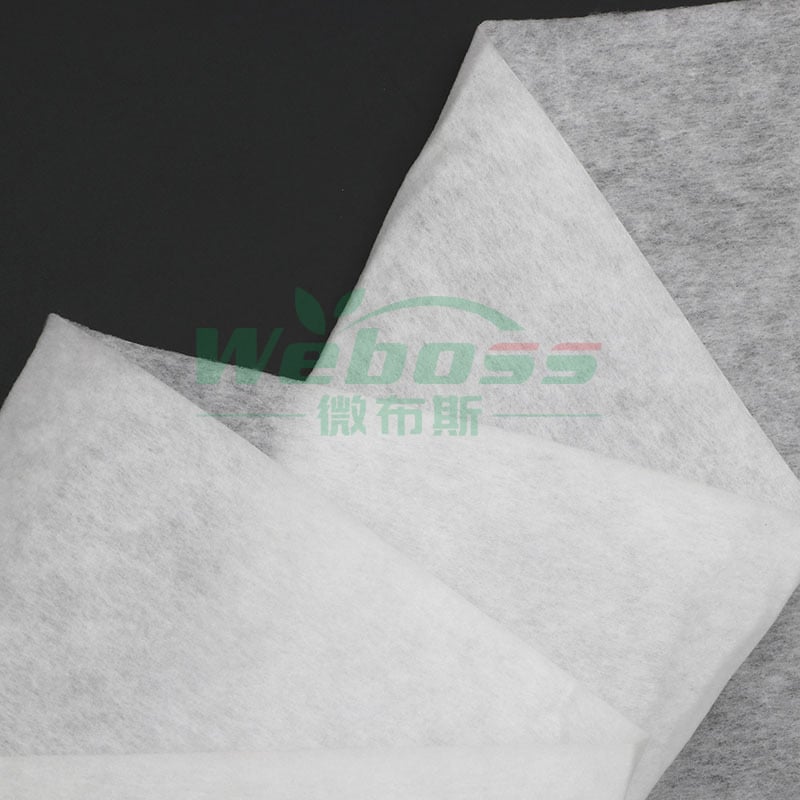

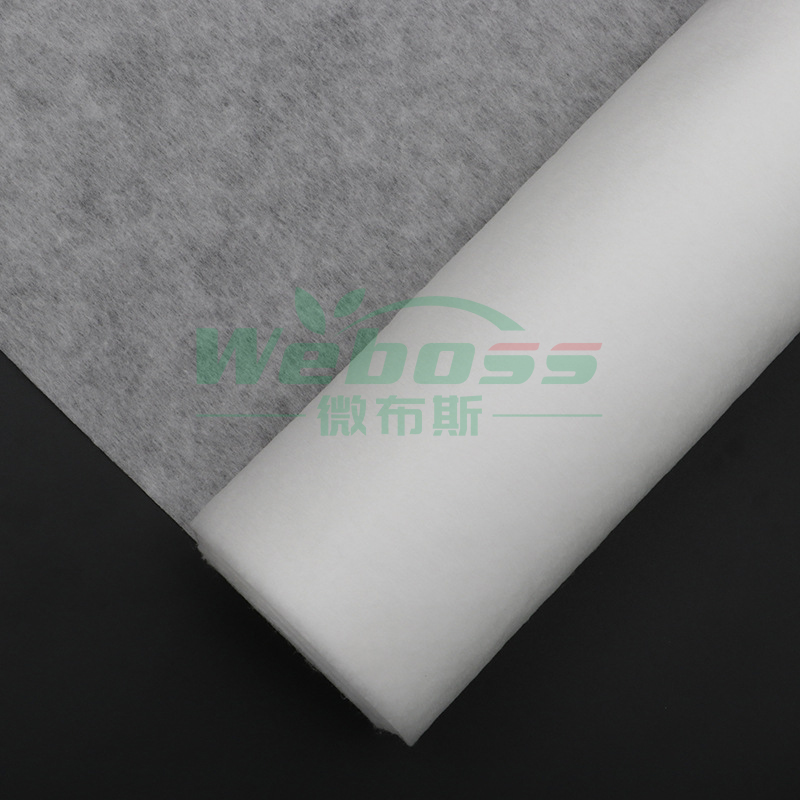

Hot air nonwoven fabric is produced by passing hot air through a layered web of fibers, which melts the low-melting-point component of the fibers and bonds them together. The resulting material is lightweight, elastic, and highly breathable, with a soft texture and uniform appearance.

Among them, ES (Ethylene-Propylene or Ethylene-Polyester) Nonwoven Fabric is made from bicomponent fibers such as PP+PE or PET+PE, while 100% Cotton Hot Air Nonwoven Fabric uses pure natural cotton fibers. Both types are safe for skin contact and suitable for a wide range of hygienic and medical applications.

Types of Hot Air Nonwoven Fabric

-

ES Hot Air Nonwoven Fabric (PP+PE or PET+PE)

-

Made from bicomponent fibers with a low-melting PE sheath and a PP or PET core.

-

Offers softness, uniform structure, and thermal bonding strength.

-

Commonly used in baby diapers, sanitary napkins, and mask inner layers.

-

-

100% Cotton Hot Air Nonwoven Fabric

-

Made from pure natural cotton fibers, providing excellent moisture absorption, breathability, and skin comfort.

-

Fully biodegradable and eco-friendly, suitable for cosmetic and medical use, such as facial mask sheets, wipes, and pads.

-

Higher in cost compared to synthetic ES nonwoven fabrics due to the natural cotton content.

-

Key Features

-

Soft and Fluffy Texture: Smooth surface and excellent drape for comfort.

-

Excellent Breathability: Open structure allows air circulation, preventing heat buildup.

-

Chemical-Free Bonding: Hot air bonding uses no adhesives, ensuring safety and purity.

-

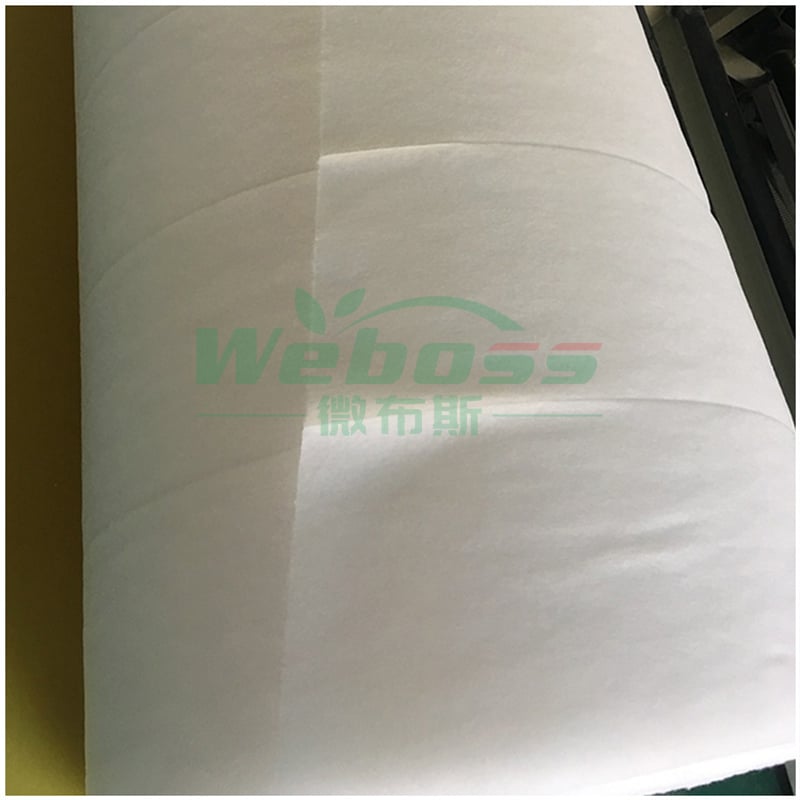

High Uniformity and Strength: Even fiber distribution for stable physical performance.

-

Skin-Friendly and Hypoallergenic: Perfect for hygiene and medical products.

-

Eco-Friendly Options: Available in biodegradable cotton or eco-modified ES fibers.

Production Process

-

Fiber Preparation:

Fibers such as PP, PE, PET, or natural cotton are selected and blended. -

Web Formation:

Fibers are carded and laid evenly to form a smooth web. -

Hot Air Bonding:

Hot air passes through the fiber web to melt the low-melting fibers (like PE sheath) and bond the structure together. -

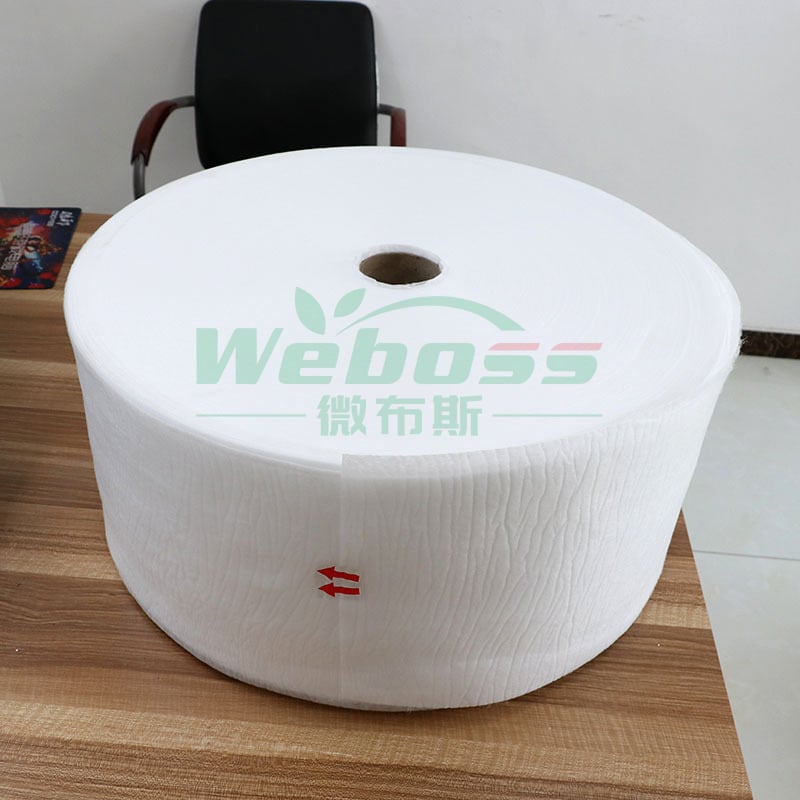

Cooling and Finishing:

The bonded fabric is cooled, softened, and wound into rolls. -

Quality Inspection:

Every roll undergoes strength, softness, and uniformity testing to ensure consistent performance.

Applications

-

Baby diapers and adult care products

-

Sanitary napkins and feminine hygiene materials

-

Mask inner and outer layers

-

Cosmetic pads

-

Medical dressings and protective fabrics

-

Air and liquid filtration materials

-

Home textile fillings and linings

Specifications

| Item | Description |

|---|---|

| Material | PP+PE, PET+PE, or 100% Cotton |

| Weight Range | 16–80 gsm (customizable) |

| Width | 15- 320 cm |

| Color | White, black, or customized |

| Pattern | Plain,dot, or embossed |

| Softness | Standard / Extra soft |

| Certification | OEKO-TEX Standard 100, ISO9001, SGS,GRS |

| Packaging | In rolls, packed with PE film or carton |

FAQ – Frequently Asked Questions

Q1: What is the difference between hot air nonwoven fabric and other nonwovens?

A1: Hot air nonwoven fabric is bonded by hot air rather than glue or water jets, resulting in better softness and fluffiness.

Q2: What are the main types of hot air nonwoven fabric?

A2: There are two main types: ES hot air nonwoven (PP+PE or PET+PE) and 100% cotton hot air nonwoven fabric. The cotton type is softer and more eco-friendly but slightly higher in cost.

Q3: Is the fabric safe for direct skin contact?

A3: Yes. All materials are non-toxic, hypoallergenic, and tested for skin safety, making them suitable for baby and cosmetic products.

Q4: Can the GSM and width be customized?

A4: Yes, we provide customizable weight, width, and pattern designs based on customer requirements.

Q5: Do you support OEM or customized production?

A5: Yes. Shanghai Weboss New Material Technology Co., Ltd. offers OEM/ODM production, flexible order quantities, and international shipping service.

Why Choose Shanghai Weboss New Material Technology Co., Ltd.

-

Advanced hot air nonwoven production lines with stable output.

-

Flexible customization options for fiber type, GSM, and softness.

-

Over 10 years of export experience in nonwoven and interlining materials.

-

Certified quality control with OEKO-TEX and ISO standards.

-

Fast global logistics and professional after-sales support.

additional information

Related Products

Stay Ahead With Weboss Updates

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.

This article explains what needle punched nonwoven fabric is, how it is made, its materials, key features, and common applications.

본 문서는 마스크용 스판레이스 부직포를 소개하며, 비스코스, 텐셀, 면, 키토산, 대나무, 해조와 같은 일반적인 섬유 옵션을 설명하고, 각 재료가 편안함과 성능에 미치는 영향을 보여줍니다.