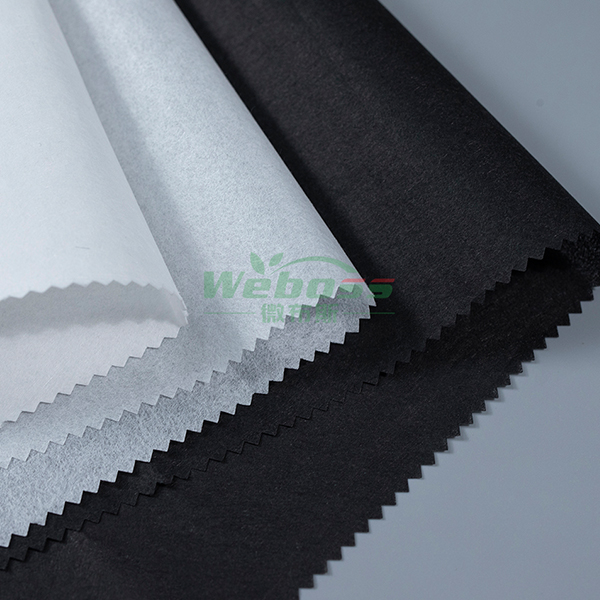

Wet Laid Nonwovn Fabric

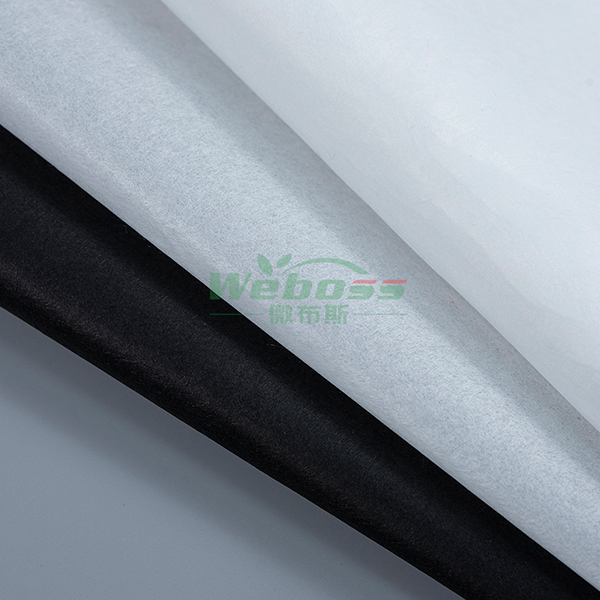

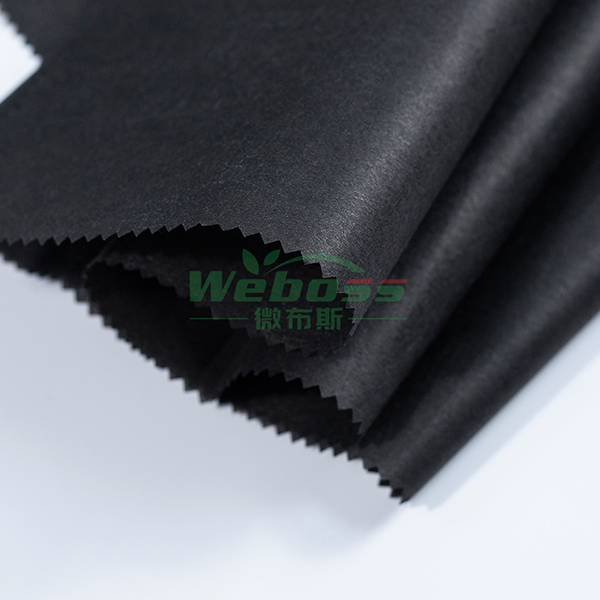

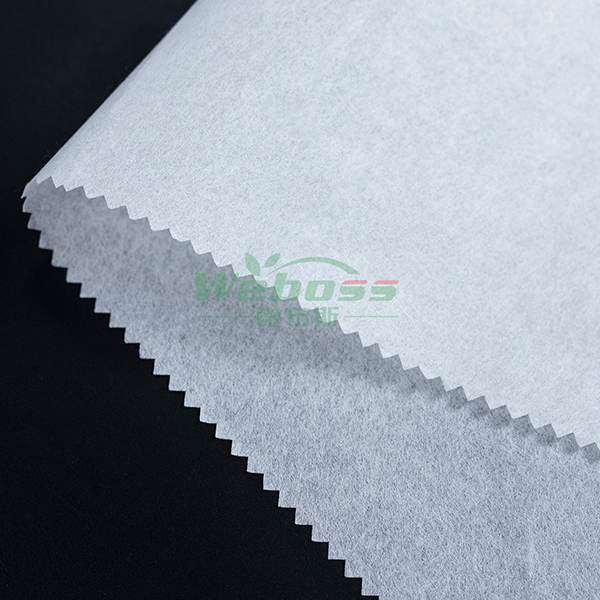

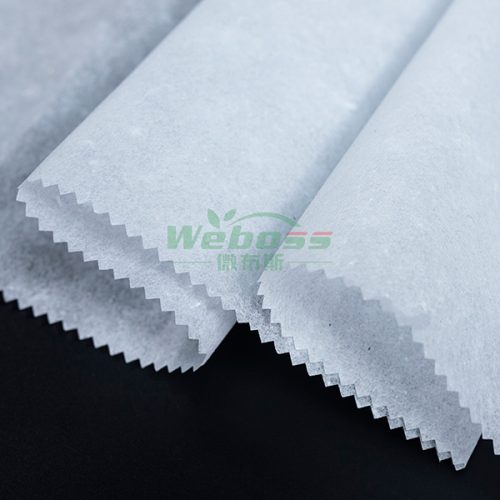

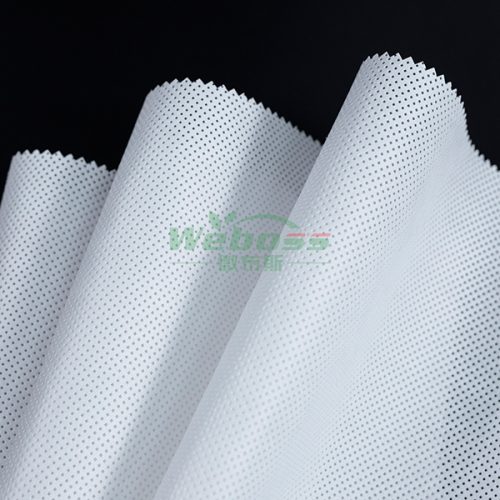

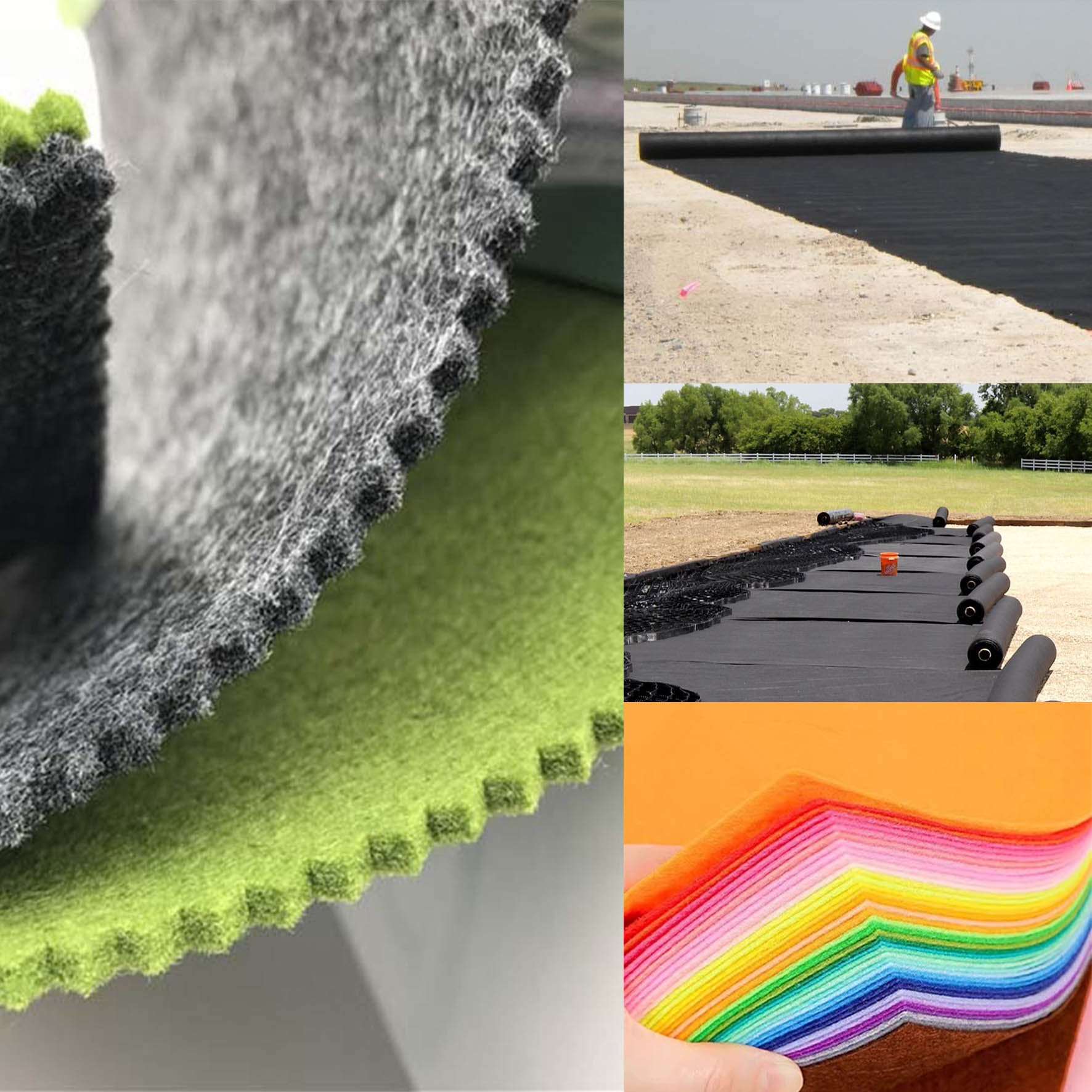

Wet Laid Nonwoven Fabric is a high-performance material produced through a wet-laid papermaking process that disperses short fibers such as cellulose, polyester, or viscose in water to form a uniform web. After chemical or thermal bonding, the fabric gains a smooth, stable, and uniform structure with excellent strength and dimensional stability.

This material is widely used in industrial filtration, battery separators, medical materials, embroidery stabilizer backing, and specialty papers due to its precision, consistency, and paper-like appearance.

product introduce

Product Description

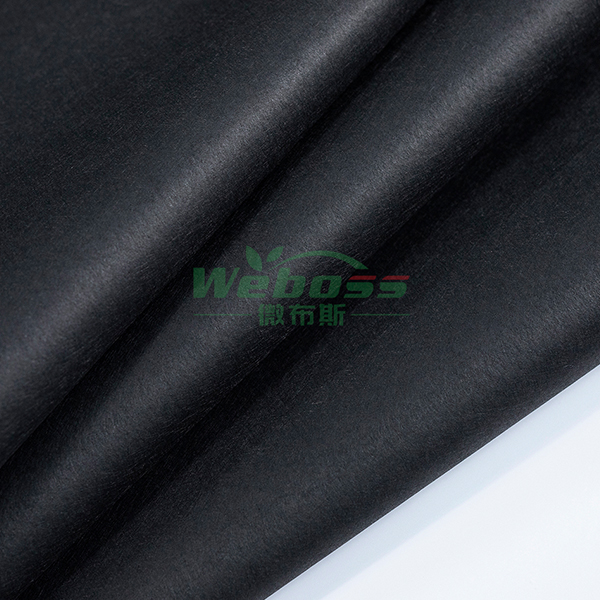

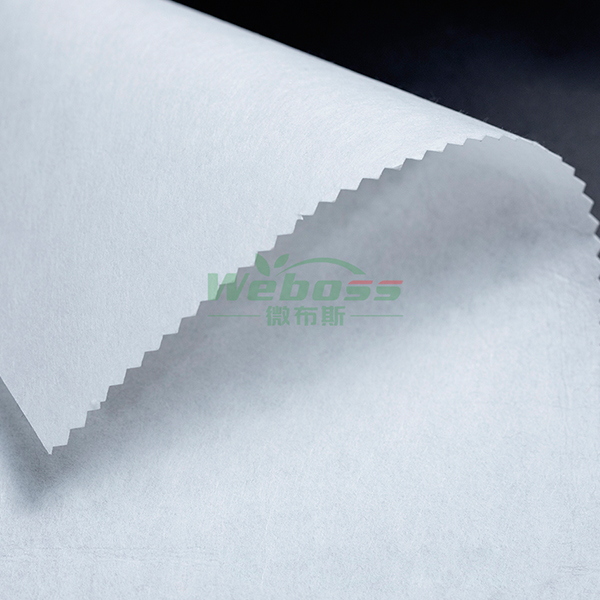

Wet laid nonwoven fabric stands out for its fine fiber distribution, smooth surface, and consistent weight. It provides a paper-like texture with superior uniformity compared to dry-laid or spunlace fabrics. These features make it suitable for technical and industrial applications requiring high stability and clean processing performance.

In garment manufacturing, it can also be used as embroidery stabilizer backing, offering clean tearability and smooth embroidery support without stretching or distortion.

Key Features

-

Excellent Uniformity: Even fiber dispersion ensures consistent structure and smooth surface.

-

High Dimensional Stability: Maintains shape and strength during processing and use.

-

Soft and Paper-like Texture: Ideal for coating, lamination, or printing applications.

-

Chemical and Thermal Resistance: Suitable for both wet and dry environments.

-

Customizable Weight and Composition: Adjustable fiber blend to meet specific application needs.

-

Biodegradable Options Available: Cellulose or viscose-based wet laid fabrics support sustainable development.

Production Process

-

Fiber Dispersion: Short fibers (cellulose, viscose, polyester, glass fiber, etc.) are dispersed evenly in water to form a slurry.

-

Web Formation: The slurry is deposited onto a moving screen to create a uniform fiber web.

-

Bonding: The web is strengthened through chemical, mechanical, or thermal bonding, ensuring stability and strength.

-

Drying & Finishing: The bonded fabric is dried, calendered, and rolled to achieve the desired thickness and surface finish.

This advanced process produces a thin, even, and durable nonwoven fabric suitable for various industrial and textile uses.

Applications

-

Embroidery Stabilizer Backing for garment decoration and embroidery support

-

Filtration Media for air, liquid, or oil filters

-

Battery Separator Materials for energy storage applications

-

Medical and Hygiene Products such as wipes, masks, and dressings

-

Lamination and Coating Substrates

-

Specialty Industrial Paper Replacements

Why Choose Shanghai Weboss New Material Technology Co., Ltd.

As a professional manufacturer and exporter of nonwoven fabrics, Shanghai Weboss New Material Technology Co., Ltd. provides customized Wet Laid Nonwoven Fabric solutions with stable quality, flexible specifications, and fast delivery. We offer OEM and ODM production to meet the requirements of different industries, from embroidery to filtration and medical use.

Our factory ensures strict quality control, global shipping support, and eco-friendly material options for sustainable production.

FAQ

Q1: What materials can be used in Wet Laid Nonwoven Fabric?

A1: Cellulose, viscose, polyester, and glass fibers are commonly used depending on the desired strength, softness, or filtration performance.

Q2: Can this fabric be used for embroidery stabilizer backing?

A2: Yes, it provides excellent strength, uniformity, and easy tearability, making it suitable for embroidery support.

Q3: Is Wet Laid Nonwoven Fabric eco-friendly?

A3: Yes, especially when using cellulose or viscose fibers, which are biodegradable and environmentally safe.

Q4: What is the typical thickness or weight range?

A4: Standard range is 15–120 gsm, customizable according to your application.

Q5: Do you offer OEM service?

A5: Yes, we provide OEM/ODM customization including fiber composition, size, and packaging design.

additional information

| Product Name | Wet Laid Nonwoven Fabric |

|---|---|

| Material | Viscose Fiber + Polyester Blend |

| Weight Range | 30-80gsm |

| Width Range | 90cm-160cm |

| Color | White, Off-White |

| Pattern | Smooth, Uniform Surface |

| Minimum Order Quantity | 5,000 meters per type |

| Price Range | USD $0.1 – $1/meter (Depending on weight and customization) |

| Packaging | Rolled on paper cores, packed in waterproof PE plastic bags with outer woven polybag |

| Transportation | Via sea, air, or express logistics |

| Payment Terms | L/C, D/P, T/T, Western Union, PayPal |

| Delivery Time | 7-15 days based on order size |

| Monthly Production Capacity | 2,500,000 meters |

| Roll Length | 50m-300m/roll (Customizable) |

| Special Customization | Available for width, weight, and material composition upon request |

| Certification | OEKO-TEX, SGS, ISO9001 |

Related Products

Stay Ahead With Weboss Updates

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.

This article explains what needle punched nonwoven fabric is, how it is made, its materials, key features, and common applications.

본 문서는 마스크용 스판레이스 부직포를 소개하며, 비스코스, 텐셀, 면, 키토산, 대나무, 해조와 같은 일반적인 섬유 옵션을 설명하고, 각 재료가 편안함과 성능에 미치는 영향을 보여줍니다.