Spunlace Nonwoven Fabric and Its Wide Applications

Summary

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding. This process preserves fiber structure and delivers a combination of softness, absorbency, and controlled strength. Common fibers include viscose, polyester, cotton, and Tencel, making spunlace suitable for applications requiring direct skin contact or liquid management. Spunlace nonwoven fabric is widely used in wet wipes, facial masks, medical disposables, and industrial cleaning products, where performance depends on fiber composition, basis weight, and entanglement density. Compared with spunbond or meltblown nonwovens, spunlace is typically selected for scenarios prioritizing absorbency and tactile comfort. Manufacturers such as Weboss supply application-specific spunlace solutions for hygiene, medical, cosmetic, and industrial markets, supporting consistent quality and scalable production.

Introduction

Spunlace nonwoven fabric has become an important material choice in wipes, medical disposables, facial masks, and industrial cleaning products. Its binder-free structure, controlled strength, and adaptability to different fiber systems allow manufacturers to address both performance and regulatory requirements. This article explains the technical definition of spunlace non-woven fabric, outlines the manufacturing process, and discusses application-driven selection, with a focus on medical, hygiene, and industrial use cases.

Spunlace Definition: What Is Spunlace Nonwoven Fabric?

Spunlace nonwoven fabric, also referred to as hydroentangled nonwoven, is a mechanically bonded nonwoven material formed by entangling loose fibers using high-pressure water jets. Unlike thermally bonded or chemically bonded nonwovens, spunlace fabrics achieve structural integrity without adhesives, resins, or thermal fusion.

According to definitions used by EDANA (European Disposables and Nonwovens Association) and INDA (Association of the Nonwoven Fabrics Industry), spunlace belongs to the family of mechanically bonded nonwovens, where fiber cohesion is created through physical entanglement rather than melting or chemical curing. This distinction explains many of its functional properties, including softness, drape, and absorbency.

Fibers commonly used in spunlace include:

- Viscose (rayon)

- Polyester

- Cotton

- Lyocell / Tencel™

- Fiber blends with wood pulp

Because fiber morphology is preserved during hydroentanglement, spunlace fabrics retain textile-like characteristics while remaining compatible with large-scale industrial production. This makes it suitable for products requiring direct skin contact, such as facial mask spunlace nonwoven fabric and medical spunlace nonwoven fabric, as well as more demanding applications like industrial spunlace nonwoven wipes.

Spunlace Non-Woven Fabric Process

The spunlace non-woven fabric process is centered on hydroentanglement, a mechanical bonding method that transforms a loose fiber web into a coherent fabric. The process consists of several controlled stages.

Web Formation

The process begins with fiber opening, blending, and web formation, typically through carding or air-laying. Fibers are distributed uniformly but remain unbonded at this stage. Fiber selection and blend ratios are determined by the intended application, such as absorbency for wipes or strength for industrial use.

Hydroentanglement

The loose web passes under rows of fine nozzles that eject high-pressure water jets. These jets penetrate the web, forcing fibers to loop, twist, and wrap around each other. The web is supported by a perforated drum or patterned belt, which influences surface texture and fabric appearance.

The number of jet manifolds, water pressure, and line speed directly affect:

- Tensile strength

- Surface smoothness or texture

- Aperture formation

- Fabric density

Dewatering and Drying

After entanglement, excess water is removed through vacuum extraction. The fabric is then dried using thermal dryers. No chemical binders are introduced during this process, which is a key difference compared with many other nonwoven technologies.

Finishing

Depending on end use, spunlace fabrics may undergo additional treatments such as:

- Hydrophilic finishing

- Antibacterial treatment

- Antistatic treatment

- Cutting, slitting, and rewinding

This process flexibility allows manufacturers to produce spunlace non-woven fabric for wet wipes, facial masks, and industrial cleaning materials on the same production platform with different specifications.

Why Choose Spunlace Nonwoven Fabric?

Spunlace is selected not because it replaces all other nonwovens, but because it performs reliably in specific usage scenarios. The table below highlights where spunlace is typically chosen compared with other nonwoven technologies.

| Application Requirement | Spunlace Nonwoven Fabric | Spunbond Nonwoven | Meltblown Nonwoven |

| Softness and drape | High | Medium | Low |

| Liquid absorbency | High | Low | Medium |

| Skin contact suitability | Suitable | Limited | Not suitable |

| Lint control | Low lint | Low lint | Higher lint |

| Mechanical strength | Adjustable | High | Low |

| Binder-free structure | Yes | Yes | Yes |

| Typical use scenarios | Wipes, masks, medical, cleaning | Packaging, hygiene backsheets | Filtration |

Spunlace is commonly chosen for:

- Products requiring direct skin contact

- Applications needing high absorbency with controlled strength

- Situations where chemical binders are restricted

For example, facial mask spunlace nonwoven fabric prioritizes softness and liquid retention, while industrial spunlace nonwoven materials emphasize durability and low particle shedding.

Weboss spunlace nonwoven fabric

Applications of Spunlace Nonwoven Fabric

Spunlace Nonwoven Fabric for Wet Wipes

Wet wipes rely on absorbency, wet strength, and low linting. Spunlace fabrics, especially viscose or blended types, provide consistent liquid uptake and structural stability during use.

Spunlace Nonwoven Fabric for Wet Wipes

Facial Mask Spunlace Nonwoven Fabric

In cosmetic sheet masks, spunlace serves as the carrier for essence and active ingredients. Tencel spunlace and viscose-based spunlace are commonly used due to their smooth surface, breathability, and compatibility with cosmetic formulations.

Facial Mask Spunlace Nonwoven Fabric

Medical Spunlace Nonwoven Fabric

Medical applications include patient wipes, surgical preparation wipes, and disposable care products. Binder-free construction and controlled cleanliness make spunlace suitable for regulated healthcare environments.

Industrial Spunlace Nonwoven

Industrial wipes require higher tensile strength, abrasion resistance, and solvent compatibility. Polyester or blended spunlace fabrics are widely used in equipment maintenance, electronics cleaning, and manufacturing environments.

Why Choose Weboss?

As a non-woven spunlace fabric manufacturer, Weboss supplies spunlace non-woven fabric for hygiene, medical, cosmetic, and industrial markets. According to product information published by Weboss, its spunlace range covers multiple fiber systems and specifications to support different applications.

Weboss spunlace nonwoven fabric features:

- Multiple fiber options, including viscose, polyester, and Tencel Spunlace

- Adjustable basis weights for light-duty to industrial use

- Consistent roll quality for automated converting

- Compatibility with wet wipes, facial masks, and medical disposables

Weboss focuses on application-oriented production rather than generic output, supporting customers in selecting fabric structures based on end-use requirements such as absorbency, strength, and surface texture.

FAQs

Q1: What is the difference between spunbond and spunlace?

A1: Spunbond nonwovens are made by thermally bonding continuous filaments, resulting in higher stiffness and lower absorbency. Spunlace fabrics are mechanically bonded using water jets, offering greater softness and absorbency, making them more suitable for wipes and skin-contact products.

Q2: Is spunlace biodegradable?

A2: Biodegradability depends on fiber composition. Spunlace made from viscose, cotton, or Tencel fibers is biodegradable, while polyester-based spunlace is recyclable but not biodegradable.

Q3: How to check spunlace fabric quality?

A3: Quality evaluation includes basis weight consistency, tensile strength, absorbency rate, linting performance, and visual inspection for uniform entanglement. Application testing under real-use conditions is also recommended.

Conclusion

Spunlace nonwoven fabric is a mechanically bonded material designed for applications where softness, absorbency, and binder-free construction are required. From spunlace nonwoven fabric for wet wipes to medical spunlace nonwoven fabric and industrial spunlace nonwoven, its performance depends on fiber selection, process control, and application alignment. For detailed specifications, sampling, or application support, contact us to discuss your requirements with the technical team.

continue reading

Related Posts

Spunlace nonwoven fabric is a mechanically bonded material produced by entangling fibers with high-pressure water jets rather than thermal or chemical bonding.

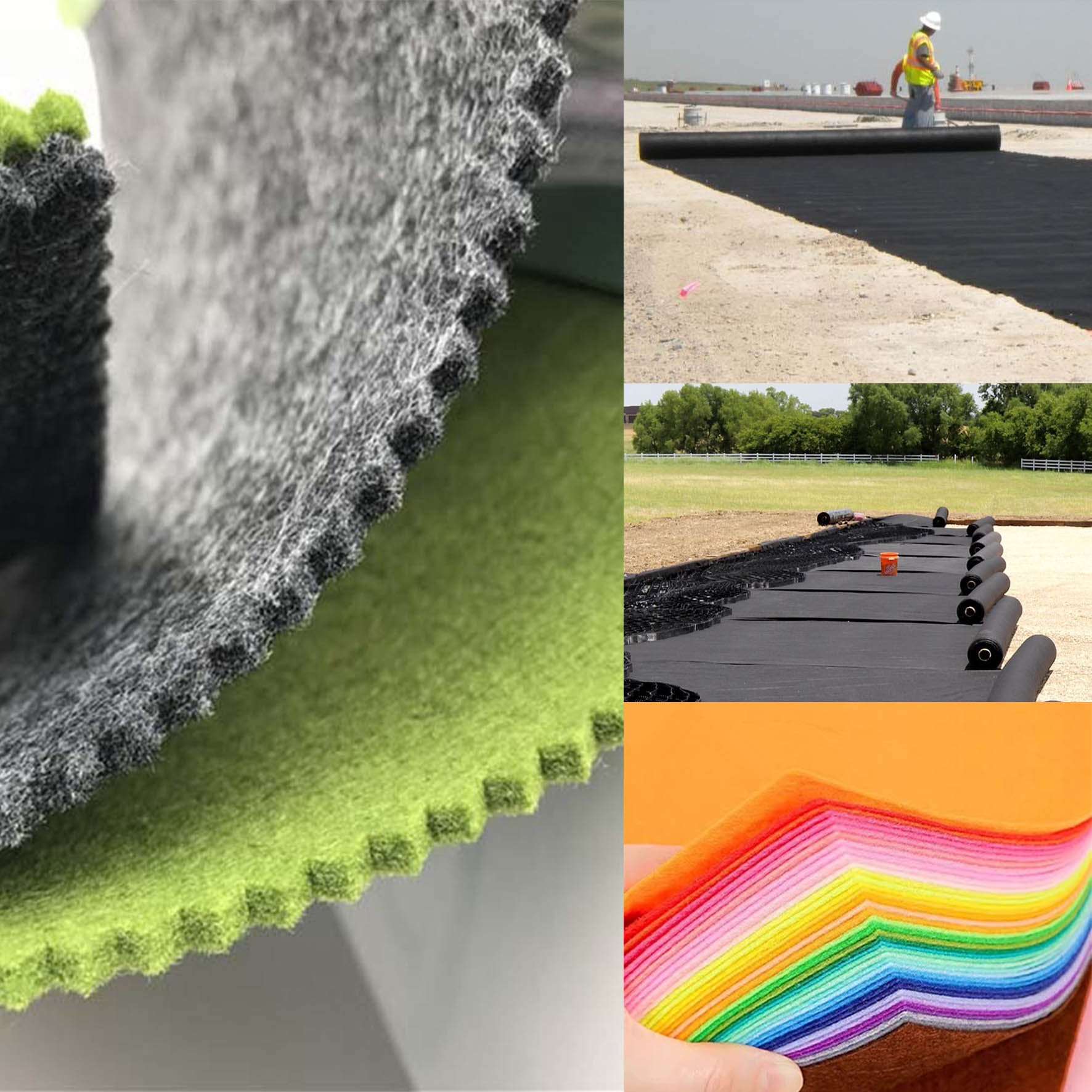

This article explains what needle punched nonwoven fabric is, how it is made, its materials, key features, and common applications.

This article explains nonwoven geotextile fabric, its materials, functions, applications, and how it works in real projects.